Kipeo‘s specialisation is customization. Every product carries an identity. The journey starts with colors and design. We work based on pantone colors, can supply the customer sample color catalogues.

Digital printing:

• Mimaki large format printers

• variable data printing; names and numbers

• quality; European supply of consumables such as ink and paper

• Mimaki large format printers

• variable data printing; names and numbers

• quality; European supply of consumables such as ink and paper

Modelling service.

•customized models

•optimization in regard with fabrics and accessories

• private label: we produce custom teamwear for third party brands.

•customized models

•optimization in regard with fabrics and accessories

• private label: we produce custom teamwear for third party brands.

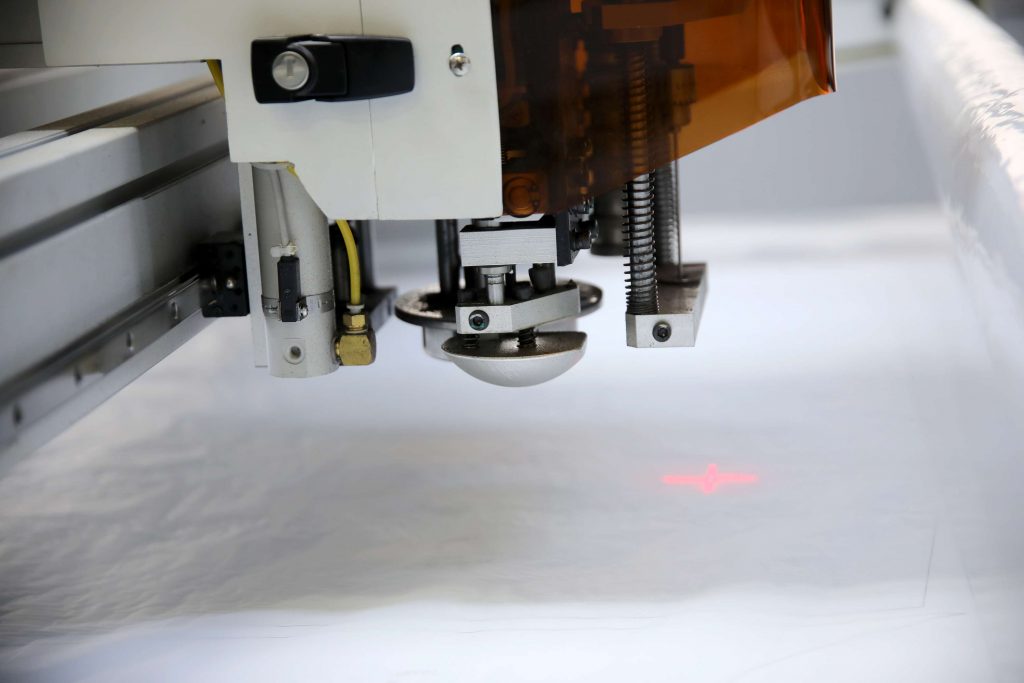

Customers main worry is, getting the same sizes again and again. In order to maintain standardization and constant quality we are using automatic cutting technique.

Digital printing needs sublimation to print the design on fabric. This is a gassing technique, for which we are using calendar press. Under a temperature of 210C° this transfer is excecuted.

Sewing department, in the hart of production we are using modern, up-to-date machinery so that the user gets best possible comfort while wearing.

Final inspection:

•check of sizes

•comparing design with product

•sewing details check

•check of sizes

•comparing design with product

•sewing details check